When violins appeared about 400 years ago, violin makers were not considered artists. Compared with other craftsmen, such as carvers, violinmakers were doing something second-rate. Despite this, they tried to make original products, and used their imagination freely.

As a result of the Industrial Revolution, most products today are produced for consumption, thus making them more difficult to recycle. Contemporary violin factories are not an exception. For example, you should never put a broken violin, glued by a disperse glue and polished by polyurethane varnish in the oven. It would contaminate the environment!

However, making quality violins by hand has been very difficult during the past 400 years, and therefore their production has become an art. Every contemporary violinmaker decides how much they will implement industrial methods into their work, thus determining which category their work will be ranked.

Only some handcrafted violins age to be valuable, and the future worth of my instruments is yet to be revealed. Nevertheless, my commitment is clear:

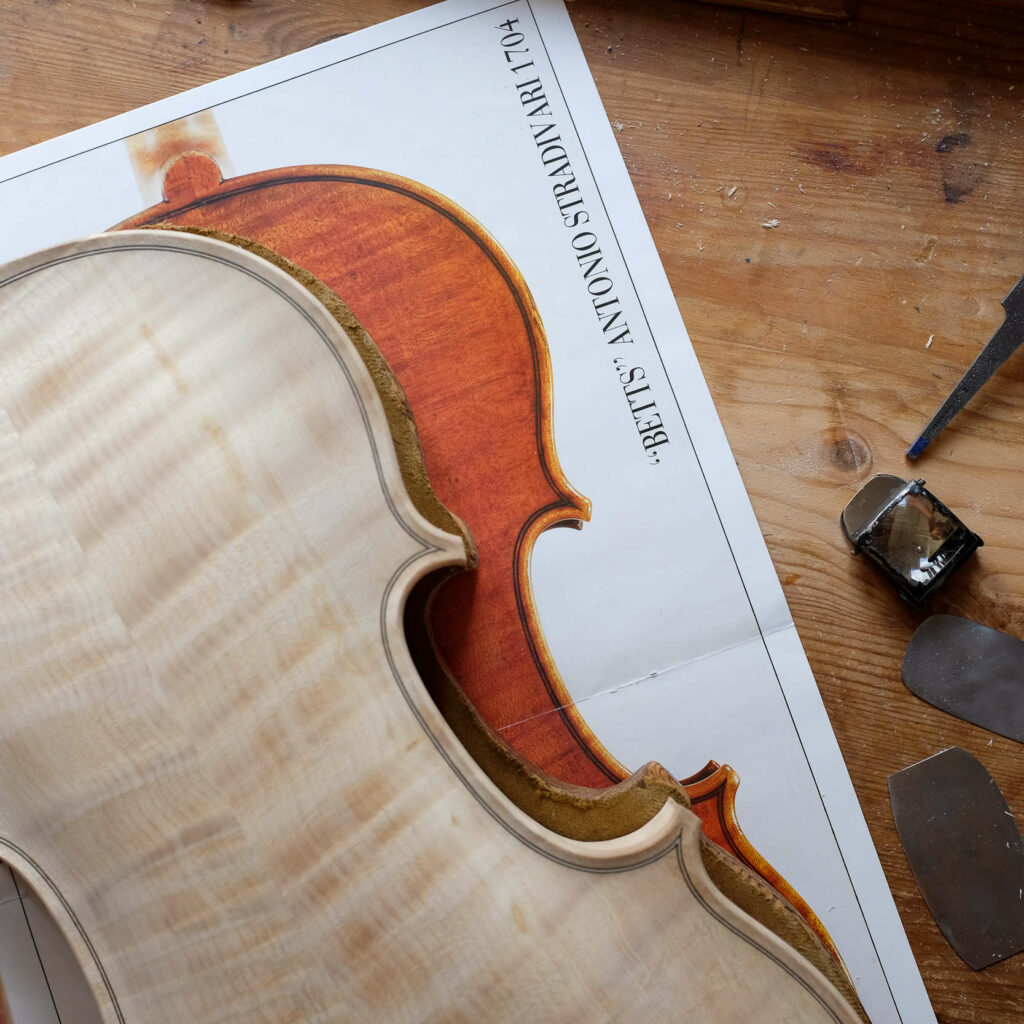

In the beginning of my career, I tried making violins in series. I used machines to speed things up and achieve perfection, for instance spraying varnishes with a compressor airbrush. The instruments were precise and flawless, they even succeeded in competitions, but they just didn’t feel right — they were not handcrafted with care. They were not the products that I wanted to put my name on.

This led me to a decision to do my best working only with my hands. It was tempting to let machines shape the wood to speed up the work, and use modern tools such as the micrometer, imbuskeys, and auto keys. But I knew that when modern tools are involved, violin makers tend to loose their own senses, knowledge, and the skills needed to work with the chisel, plane, scrape blade, and knife…

Machinery production can no longer be called an artistic craft. Instruments made by these methods radiate an artificial, displeasing effect that is immediately recognized by experts and sensed by laymen. I didn’t want to compete with the perfectionism, sterility and coldness of machine-made instruments… and rather than producing series of cold machine-made instruments, I resolved to focus on handcrafting a small number of the finest ones.

I can already hear your objection, “What about Stradivari who made 500, or maybe even 1000 violins?” The truth is that Antonio Stradivari worked until the unbelievably old age of 93 years, aided by his two sons, Francesco and Omobono, who did not build a single instrument under their own names while their father was alive. They too died as very old men within a few years of one another. Still, when we omit the apprentices and friends who worked with them, they had to have been very diligent.

My violins have an improvised inward form, making every piece is unique. When a violinmaker starts with this way of work he finds out that old technological procedures are not entirely forgotten and the “secret” of varnish has its own logical historical development.

I spent several years traveling to see precious instruments that, by their expressive character, reveal how they were built and what kind of people produced them. Therefore I would be very proud if you could recognize, or at least feel, the enthusiasm, knowledge and skill that I make my violins with.

Famous Czech violinmaker Věnceslav Metelka said:

I would like to be proud of my violin 400 years from now! I wish you a lot of fun in your playing and deciding which violin, viola or violoncello to buy!